What Is Activated Sludge?

Activated sludge is the core biological process used in modern wastewater treatment plants. It refers to a mixture of microorganisms and organic solids suspended in water that break down pollutants under aerated conditions. This biological treatment system converts dissolved and colloidal organic matter into stable biomass and clear effluent.

The term “activated” describes how the sludge contains active microorganisms mainly bacteria, protozoa, and fungi—that feed on organic waste. When aeration stops, these floc-forming microorganisms settle easily, separating treated water from biomass in a secondary clarifier.

Key concept:

Activated sludge is both a process and a biological mass. Its effective control determines the efficiency, stability, and environmental safety of the entire wastewater treatment chain.

Principles of the Activated Sludge Process

The activated sludge process relies on a continuous biological cycle:

- Aeration: Wastewater and microorganisms mix in an aeration tank. Air or pure oxygen is diffused to maintain dissolved oxygen and support aerobic degradation.

- Sedimentation: The mixture (called mixed liquor suspended solids, MLSS) flows into a secondary clarifier where sludge settles.

- Return and waste: A portion of settled sludge (RAS – return activated sludge) is recycled to maintain microbial population; the excess (WAS – waste activated sludge) is removed for further treatment.

Composition of Activated Sludge

Activated sludge is a complex biological suspension, consisting mostly of water (over 95%) and a small fraction of solids.

Physical and Chemical Components

- Water content: 90–98%

- Solids (dry matter): 2–10% after thickening

- Organic matter: 50–70% of dry solids (carbon, hydrogen, oxygen)

- Nutrients: nitrogen (15–18%), phosphorus (1–1.5%), potassium, calcium, magnesium

- Inorganics: sand, clay, salts, heavy metals (Cd, Cu, Zn, Pb, etc.)

Microbiology of Activated Sludge

Activated sludge hosts a vibrant microbial ecosystem:

- Bacteria: main degraders of organic carbon and nutrients

- Protozoa and rotifers: control bacterial population, improve floc structure

- Fungi and nematodes: participate in decomposition under special conditions

This biological diversity ensures effective breakdown of contaminants and stable floc formation, which is critical for sludge settling.

Types of Sludge in Wastewater Treatment

Primary Sludge

Formed during primary sedimentation, it contains coarse solids and organic matter that settle out before biological treatment.

- Water content: ~93–97%

- Organic solids: 70–80% of dry matter

- pH: slightly acidic (5.5–6.5)

Secondary or Activated Sludge

Produced during biological treatment. It consists mainly of microbial biomass and fine particles.

- Water content: 95–98%

- High in living microorganisms

- pH: near neutral (6.5–7.5)

Waste Activated Sludge (WAS)

The excess sludge removed from the aeration system to maintain a balanced biomass concentration. It contains dead cells and inert residues.

Digested and Chemical Sludges

- Digested sludge: stabilized via anaerobic or aerobic digestion; darker, denser, less odor.

- Chemical sludge: produced when using coagulants (Fe, Al salts) to remove phosphorus or enhance clarification.

🧭 Quick comparison:

| Type | Water % | Organic % (VS) | pH | Description |

|---|---|---|---|---|

| Primary | 93–97 | 70–80 | 5.5–6.5 | Settled solids before aeration |

| Secondary | 95–98 | 80–90 | 6.5–7.5 | Biological floc biomass |

| Digested | 70–85 | 55–65 | 7–8 | Stabilized, reduced odor |

Waste Activated Sludge Treatment Stages

Once excess sludge is removed, it undergoes several stages to reduce volume, eliminate pathogens, and recover resources.

Thickening

Removes free water, increasing solids concentration from ~1% to 3–6%.

Methods: gravity settling, flotation, or centrifugation.

Stabilization and Digestion

Goal: Decompose organic matter, reduce odors, destroy pathogens.

- Anaerobic digestion: In oxygen-free conditions, bacteria produce biogas (CH₄ + CO₂). Ideal for large facilities with energy recovery systems.

- Aerobic stabilization: Oxygen is supplied; reduces volatile matter with lower energy output.

Dewatering, Drying, and Incineration

- Mechanical dewatering (centrifuge, filter press) raises solids to 20–30%.

- Thermal drying lowers moisture below 15%.

- Incineration or co-incineration in cement kilns reduces volume and eliminates contaminants.

Applications and Resource Recovery

Agricultural Use and Composting

Up to 80% of treated sludge in countries like Spain and the UK is used in agriculture as soil conditioner. It enriches soil with organic matter and nutrients (N, P, K), improving fertility and structure.

Composted sludge combined with plant waste forms high-quality biosolid compost for landscaping and horticulture.

Energy Recovery

- Biogas from anaerobic digestion is a renewable energy source.

- Co-incineration in cement kilns recovers heat and materials.

- Dry sludge pellets can serve as auxiliary fuel.

Industrial and Construction Uses

Research explores using dried sludge in brick manufacturing, cement blends, or biofilters to adsorb contaminants.

Environmental and Health Risks

Improper sludge management can cause significant environmental and public health risks.

Biological Contamination

Contains pathogens such as E. coli, Salmonella, Clostridium, viruses, and helminths.

➡ Requires disinfection or pasteurization before agricultural use.

Heavy Metals and Organic Pollutants

Metals (Cd, Pb, Ni, Zn) and organic micropollutants (pharmaceuticals, endocrine disruptors) can bioaccumulate in soils and crops.

Odors, Gas Emissions, and Leachates

Poorly stabilized sludge emits H₂S, NH₃, and greenhouse gases (CH₄, CO₂).

Leachates from landfills may contaminate groundwater.

🛡️ Control measures:

- Strict monitoring (metal limits, pathogen tests)

- Proper stabilization and regulated land application

- Emission control in incineration systems

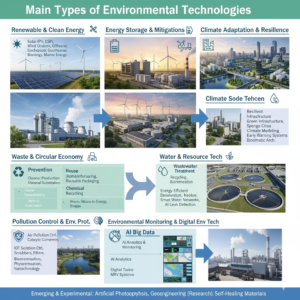

Towards Sustainable Activated Sludge Management

The future of wastewater treatment lies in resource recovery, energy efficiency, and circular economy models:

- Recovering nutrients (phosphorus, nitrogen)

- Generating renewable biogas

- Reusing treated water safely

Sustainability means viewing sludge not as waste, but as a valuable by-product that supports green energy and soil restoration.

Frequently Asked Questions (FAQ)

Q1. What is the difference between activated and primary sludge?

Primary sludge comes from settling tanks before biological treatment; activated sludge is the microbial mass formed during aeration.

Q2. How is waste activated sludge treated?

Through thickening, digestion, dewatering, and sometimes incineration, depending on final use or regulation.

Q3. Can activated sludge be reused?

Yes. Stabilized and treated sludge (biosolids) can be safely used in agriculture or energy recovery.

Q4. Why is anaerobic digestion important?

It stabilizes sludge, eliminates pathogens, and produces renewable biogas.

Bibliographic References

- Real Decreto 1310/1990, de 29 de octubre, por el que se regula la utilización de los lodos de depuración en el sector agrario. Boletín Oficial del Estado, núm. 262, 01/11/1990

- Real Decreto 1481/2001, de 27 de diciembre, por el que se regula la eliminación de residuos mediante depósito en vertedero. Boletín Oficial del Estado, núm. 25, 29/01/2002

- Orden AAA/1072/2013, de 7 de junio, sobre utilización de lodos de depuración en el sector agrario. Boletín Oficial del Estado, núm. 142, 14/06/2013

- Ley 7/2022, de 8 de abril, de residuos y suelos contaminados para una economía circular. Boletín Oficial del Estado, núm. 85, 09/04/2022boe.es.

- Ministerio de Medio Ambiente y Medio Rural y Marino (España). (2009). Caracterización de los lodos de depuradoras generados en España

- Barrera i, E., Andrés, P., y Alcañiz, J. M. (2001). Sewage sludge application on soil: effects on two earthworm species. Water, Air & Soil Pollution, 129, 319–332

- Doméne, X., Alcañiz, J. M., y Andrés, P. (2007). Ecotoxicological assessment of organic wastes using the soil collembolan Folsomia candida. Applied Soil Ecology, 35, 461–472

- Gómez-Orea, D. (2004). Recuperación de espacios degradados. Madrid: Mundi-Prensa